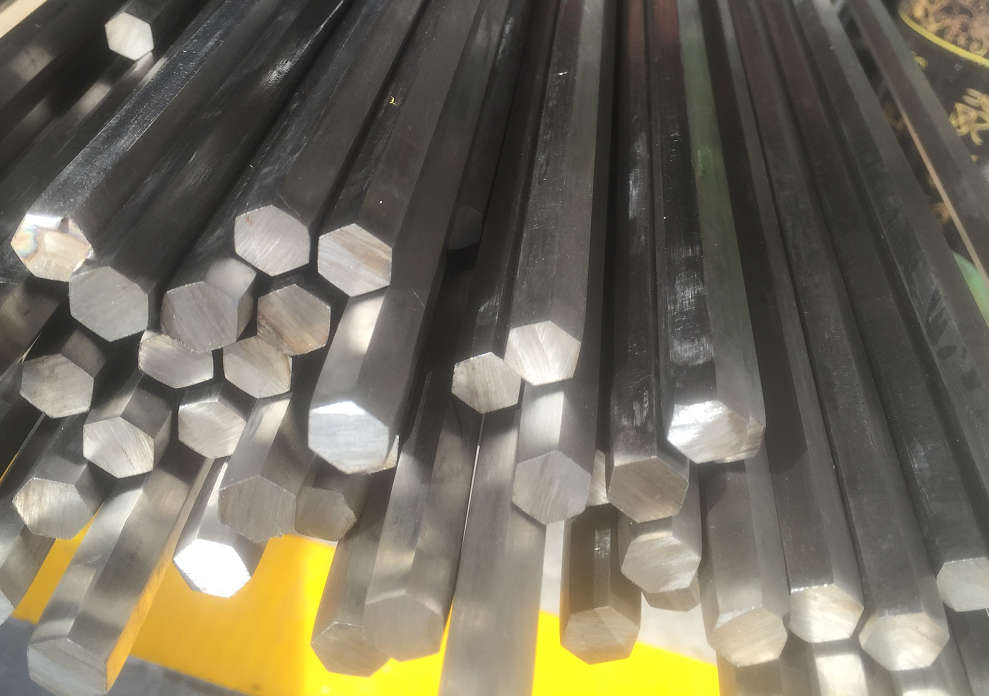

Bar baja stainless

Bar stainless steel yaiku materi sing digawe saka playet panas utawa ngapikake ingots stainless steel steel. Miturut standar klasifikasi sing beda, bar stainless steel bisa dipérang dadi pirang-pirang jinis.

Baja bunder, baja alun, baja sing rata, baja hexagonal lan baja octagonal sacara kolektif diarani bar stainless steel.

Spesifikasi lan Bahan

Spesialisasi bar baja stainless: bar stainless stainless stainless kanthi ukuran (diameter, sisih dawa, kekandelan utawa jarak ing antarane sisih ngisor) ora ngluwihi 250mm utawa ing ndhuwur lan Ø21MC utawa ing ngisor iki.

Bahan bar stainless stainless: 304, 304L, 321, 316, 316L, 36, 630, 1Cr17, 3Cr17ni2, baja antibakteri lan bahan liyane! [1]

Ruang lingkup

Bar stainless steel duwe prospek aplikasi sing amba lan digunakake ing hardware lan purnisi, mesin, energi, Aerospace, industri militer lan industri militer lan industri militer! Peralatan kanggo banyu laut, bahan kimia, pewarna, kertas, asam oxalic, pupuk lan peralatan produksi liyane; Industri panganan, fasilitas pesisir, tali, rod cd, bolt, kacang.

Manajemen Kualitas: ISO9001: 2000 sertifikasi sistem manajemen kualitas, 200000, lisensi produksi, lsp!

Cathetan: bar baja tahan karat saka macem-macem bahan lan spesifikasi bisa disesuaikan.

Kisaran aplikasi, aplikasi, manajemen kualitas introduksi bar baja stainless

Bahan: 304, 304L, 321, 316, 316L, 310S, 630,

Bahan umum yaiku 201, 202, 301, 303, 306, 316, 316l, 304L, 304L, 3Cr13, baja antibakteri, baja liyane lan bahan liyane! Eval spesifikasi diucapake kanthi diameter, kayata "50" tegese baja bunder kanthi diameter 50 mm. Baja bunder dipérang dadi telung jinis baja sing diluncurake 5.5-250 mm.

Range aplikasi: Minyak, elektronik, bahan kimia, obat, tekstil, panganan, mesin, mesin, tenaga nuklir, aerospace, industri militer lan industri militer!

Manajemen Kualitas: ISO9001: 2000 sertifikasi sistem manajemen kualitas, 200000, lisensi produksi, lsp!

Proses produksi

Bar stainless steel bisa dipérang dadi telung jinis miturut proses produksi: nggulung panas, lali lan gambar kadhemen. Spesifikasi baja bunder stainless steel panas sing diluncurake yaiku 5.5-250 mm. Antarane: 5,5-25 mm baja stainless steel stainless steel biasane diwenehake ing sandhangan bar lurus, asring digunakake minangka bar baja, bolts lan macem-macem bagean mekanik; Belang Putaran Stainless Steel luwih gedhe saka 25 mm biasane digunakake kanggo nggawe bagean mekanik utawa minangka blangko pipa baja lancar.

Standar Implementasi

Standar Nasional kanggo Bar Stainless Steel: GB / T14975-2002, GB / T14976-2002, GB / T13296-91

Standard American: ASTM A484 / A484M, ASTM A213 / 213a, ASTM A269 / 269m

Klasifikasi

Miturut komposisi kasebut, bisa dipérang dadi seri CR (SUS400), seri cr-ni (SUS300), CR-MN-NI (SUS200) lan seri Sus600).

200 seri Chromium-Manganitik Steel Stainless steel

300 baja stainless steel kromium-nikel nikel

301-DUCTILILture sing apik, digunakake kanggo produk cetakan. Sampeyan uga bisa diprupung kanthi kacepetan mesin. WelDability sing apik. Nganggo resistensi lan kekuatan lemes luwih apik tinimbang 304 stainless steel.

Tahan tahan karat 302 padha karo 304, nanging kekuwatane luwih apik amarga konten karbon sing cukup dhuwur.

303 - digawe luwih gampang dipotong kanthi nambah sulih lan fosfor sing sithik.

304-18 / 8 Stainless Steel. Kelas GB yaiku 06cr19NI10.

309 tahan panas sing luwih apik tinimbang 304.

316-sawise 304, baja sing paling akeh digunakake, utamane digunakake ing industri panganan lan peralatan bedhah, nambahi molybdenum kanggo entuk struktur tahan karat khusus. Amarga duwe resistensi karat corosida sing luwih apik tinimbang 304, uga digunakake minangka "baja laut". SS316 biasane digunakake ing piranti pemulihan bahan bakar nuklir. 18/10 baja stainless stainless biasane uga nyukupi level aplikasi iki.

Model 321-kajaba manawa risiko karat weld corosion dikurangi suda kanthi titanium, properti liyane padha karo 304.

400 baja stainless steel serial

408 resistensi panas sing apik, tahan karat korosi sing ringkih, 11% cr, 8% ni.

409-model sing paling murah (Inggris lan AS), biasane digunakake minangka pipa ekstra mobil, kalebu stainless steel ferritless (Chrome baja).

410-martensite (baja krom sing dhuwur), resistensi nyandhang apik, tahan karat korporsi sing kurang.

416-Sulfur ditambahake kanggo nambah properti pangolahan materi kasebut.

420- "Baja kelas" Tools "sing padha karo BrineLell Chromium baja, baja stainless sing paling awal. Uga digunakake kanggo lading bedah, bisa digawe padhang banget.

430-ferritic Stainless Steel, hiasan, kayata kanggo aksesoris mobil. Kompleksi sing apik, nanging resistensi suhu sing kurang lan tahan karat.

Baja alat 440-dhuwur, konten karbon sing luwih dhuwur, bisa entuk kekuatan asil sing luwih dhuwur sawise perawatan panas sing tepat, atose bisa tekan 58hrc, kalebu stainless steel sing paling angel. Conto aplikasi sing paling umum yaiku "Blade Blade". Ana telung model sing biasa digunakake: 440A, 440B, 440C, lan 440F (gampang diproses).

Baja kromium tahan panas 500 seri.

600 Seri-Mignensit Puncak Stainless steel steel.

630-paling akeh jaminan stainless steel stainless steel, uga umume diarani 17-4; 17% cr, 4% ni.

Wektu kirim: Feb-08-2025